Introducing the world’s first-ever eco-friendly plastics that actually degrade themselves! BioBottles™ are a revolutionary way to package your product that is both environmentally friendly and cost-effective. BioBottles™ has been created with the help of Plastic IQ™ technology, which will allow for better environmentally friendly solutions without compromising quality.

BioBottles™ are a sustainable alternative to plastic bottles that can be transformed into a more earth-friendly material by exposing it to UV light, temperature, and oxygen. Our patented technology stimulates bacteria and microorganisms into thinking they’re eating natural food sources, resulting in accelerated decay of plastic, leaving behind only oxygen, co2, and renewable organic material.

The end result? Cleaner environment without harmful chemical residue while simultaneously recycling valuable old discarded plastic into organically relevant compounds.

Bio Bottles are made in America with a 5-year shelf life before they start to biodegrade.

Bio Bottles will begin to bio-assimilate or degrade within one year when exposed to the right environmental conditions.

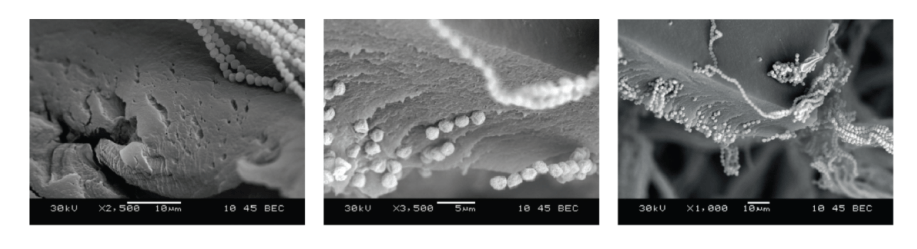

Bio Bottles are designed to be consumed by fungi, bacteria, and micro-organisms in a marine or nutrient-rich environment once disposed of in the right conditions.

Once consumed and fully degraded, Bio Bottles leave behind no microplastics and are converted into oxygen, carbon dioxide, and biomass made up of organically important compounds.

Each BioBottles™ and

BioCap™ is manufactured with “Plastic IQ™ Technology”.

When discarded and not recycled. BioBottles™ and BioCaps™ begin to degrade when exposed to UV sunlight, Oxygen, and micro-organisms.

These micro-organisms which consist of fungi and bacteria, are stimulate into thinking the plastic is actually a food source in a marine or nutrient-rich environment.

Once consumed and fully degraded, BioBottles™ and BioCaps™ leaves behind no microplastics and are converted into oxygen, carbon dioxide and biomass made up of organically important compounds.

BioBottles and BioCaps with “Plastic IQ” is a masterbatch technology which

turns ordinary plastic, at the end of its useful life, in the presence of oxygen,

into a material with a different molecular structure. At the end of the process, it is no longer a plastic, and has changed into a material which is biodegradable, by bacteria and fungi, in the open environment. With over 20 years of scientific research behind it, Plastic IQ biodegradable technology is perfect to use with most types of single-use plastic packaging and bottles.

BioBottles™ are made from 100% food-grade compliance and meet or exceed industry standards for safety. They’re also FDA compliant, meaning that they’ve been verified as free of harmful chemicals, and all BioBottles™ have gone through testing by third-party organizations to ensure quality control throughout our entire supply chain.

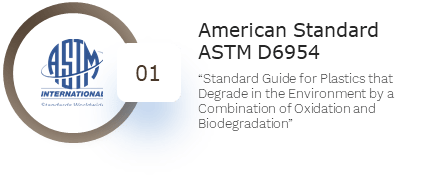

Additional to the FDA and Food-grade compliance, BioBottles™ are also compliant with the following regulations:

Please note that this information is not to be considered a commitment or warranty of any kind. The information provided is general information. We recommend you that you consult our technical department for specific applications for details on supplies and approvals available in your country/countries of interest. We do not assume responsibility if there are no regulatory restrictions present which would prohibit us from fulfilling such warranties under local law where it may apply. All advertising claims made by third parties fall under the sole responsibility of the buyer.

Automated page speed optimizations for fast site performance